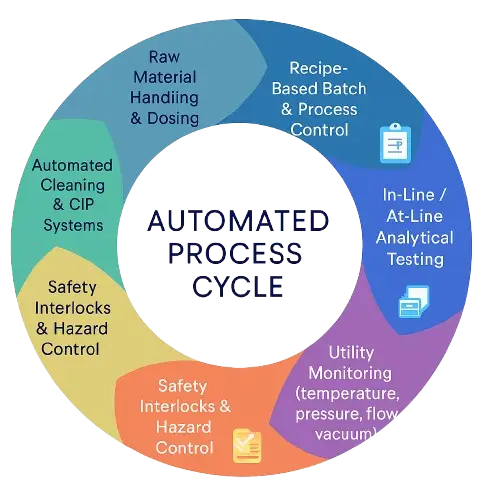

Modular & Automated Systems

Our infrastructure features flexible and scalable equipment capable of adapting to a wide range of chemical processes without compromising safety or efficiency. Each production unit is engineered to support varying batch sizes and formulations, enabling smooth transitions between research, pilot-scale, and commercial operations.

Through advanced automation, precision controls, and real-time monitoring, Hemshoolin ensures consistent product quality and optimized performance across every process. This adaptability allows us to meet diverse client needs, drive innovation, and maintain the highest standards of operational safety, environmental compliance, and productivity.

Key Equipment

Flow Reactor-Based Continuous Processing

Continuous processing for precise control, enhanced safety, and consistent product quality.

Fixed-Bed Hydrogenation Units

Closed-system catalytic hydrogenation ensuring high selectivity and safe hydrogen handling.

Melt Crystallization Systems

High-purity crystallization using solvent-free or low-solvent purification methods.

Continuous Short-Path Distillation:

Low-temperature, high-vacuum distillation ideal for heat-sensitive and high-boiling compounds.

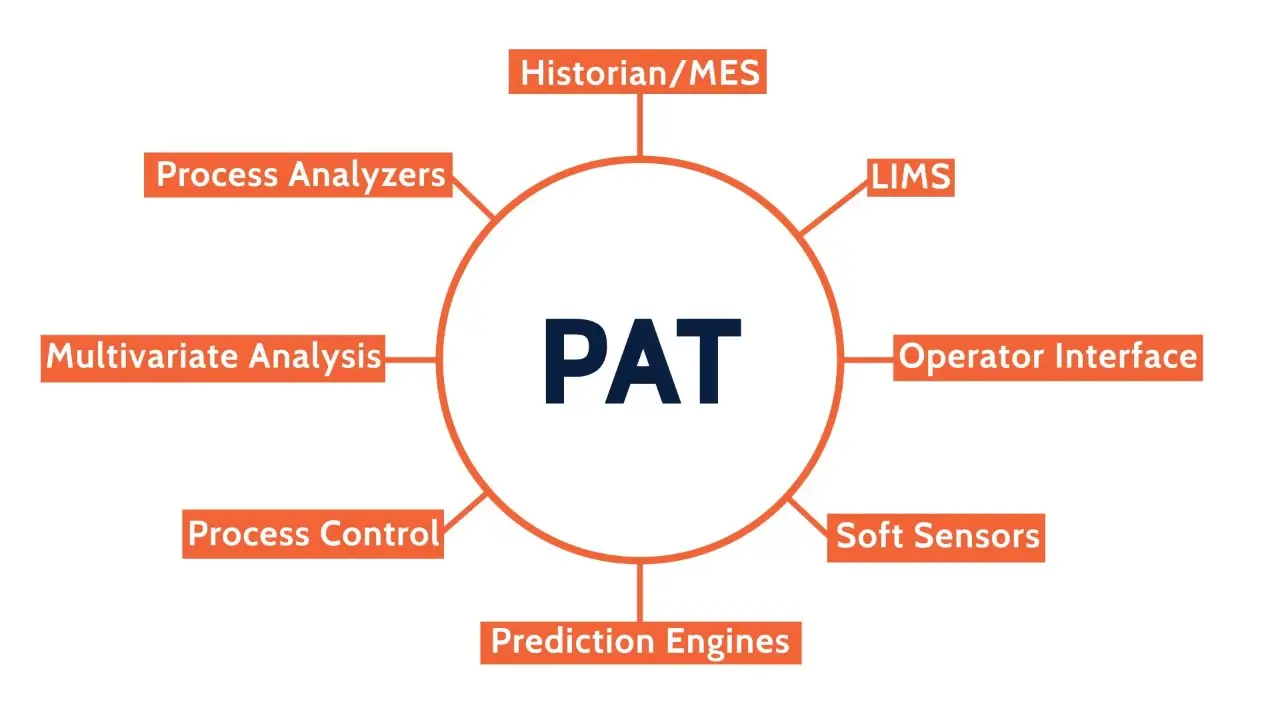

PAT Integration

Process Analytical Technology enables real-time monitoring of reactions, ensuring consistent quality and early detection of deviations

Automation & Digital Control

Safety

Reduced risk through automated control and contained processes

Precision

Consistent product quality across all batches